The DEVILS project started in Jennary 16, 2017 with the collaboration of Euro.Soft srl, Protom, A. Abete srl, CNR, Università Napoli Federico II and TAT ended successfully on May 5, 2021. The project was funded by the European Commission within the CleanSky program.

The Devils Project

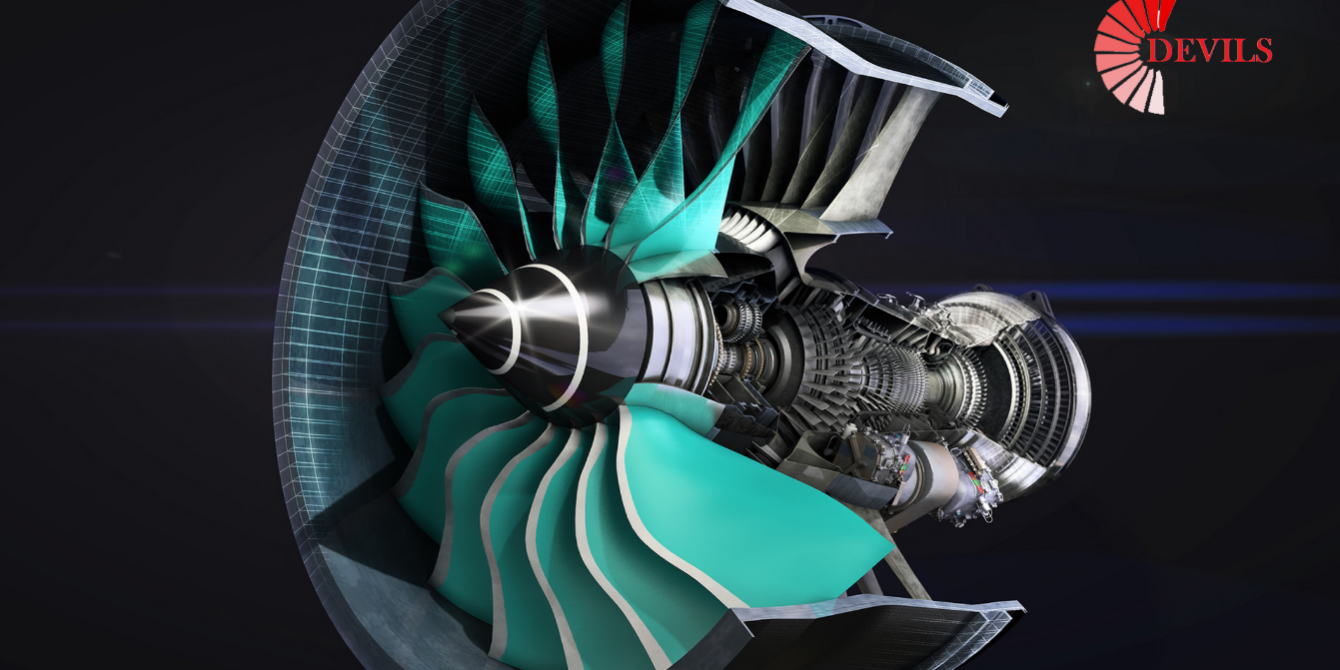

Aircraft Engines are normally assisted by a number of complementary systems that have to guarantee performance throughout the whole flight envelope of the aircrafts for which they are designed. Among these systems Oil lubrication and heat management system is the most important due to its roles:

- Remove the heat generated in the highly loaded rolling bearings and the gears found in the Engine power and accessory gearboxes

- Lubricate bearing and Power and Accessory gear boxes.

The current trend of developing aircraft engines that consume less fuel put a lot of pressure on the oil lubrication system cooling requirements due to higher speeds, loads and temperatures in engines. This is much more true for Very High Bypass Engines due to the integration of high-power gearboxes (allowing high by-pass ratio) and high-power startergenerators.

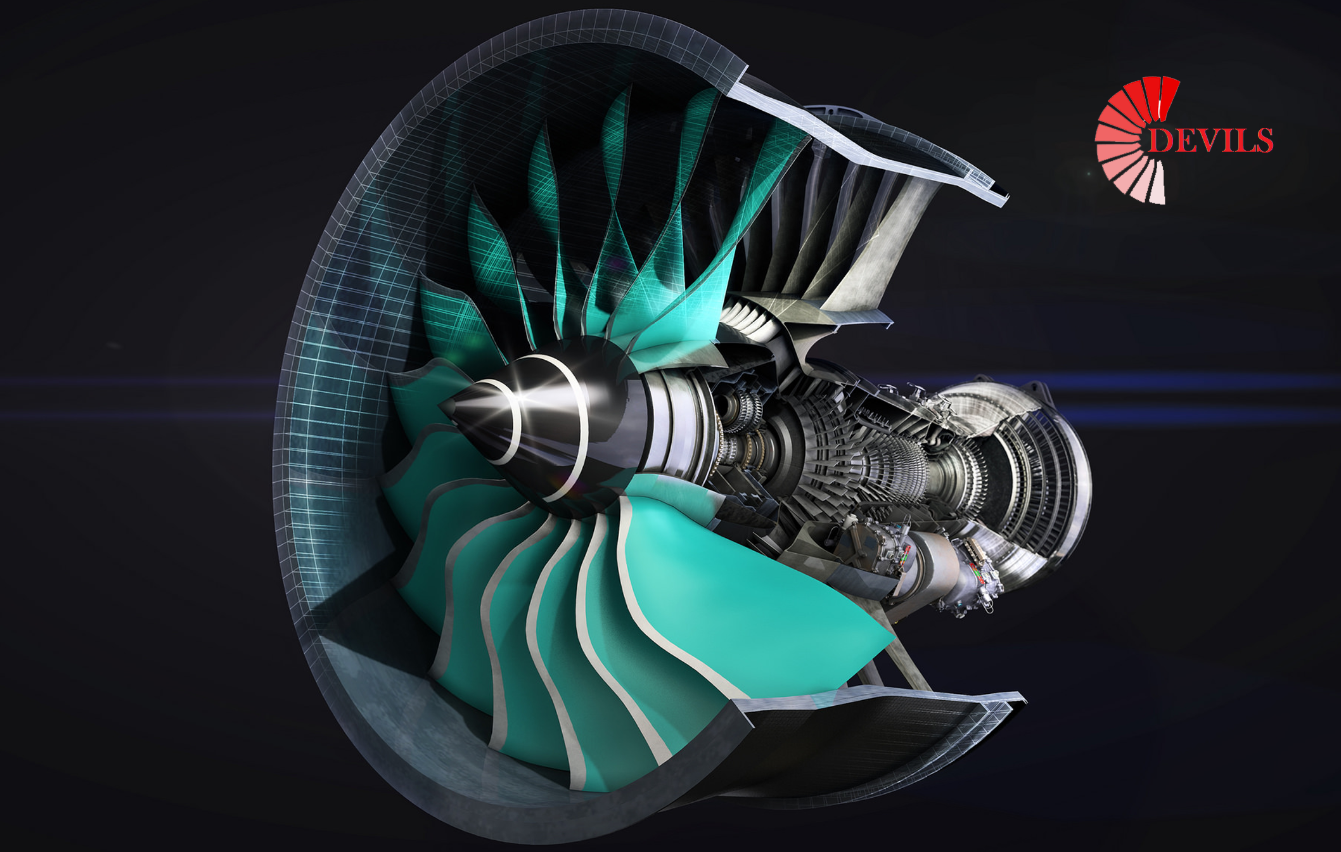

For this reason Engine manufacturer are deeply looking to innovative design for oil lubrication and heat management system implementing architectures that are able to meet the new cooling and lubricating requirements without negatively impacting the Engine weight or operational and maintenance costs. The overall objective of project DEVILS Project is to research, develop and validate the robustness of a new variable oil flow approach towards the design an innovative variable flow oil pump to be integrated in a high performance aircraft lubrication systems architecture with the aim of reducing fuel and oil consumption.

Objective of DEVILS project is as well to research, implement and validate smart fault detection and health monitoring algorithms to assist the system in reducing oil low flow rate needs and prognostic functions.

An innovative Variable Flow Rate Oil Pump

DEVILS Consortium presented a solution based on an innovative Variable Flow Rate Oil Pump concept. The final output of DEVILS project is an oil lubrication system with the innovative variable flow rate oil pump demonstrator to be tested in laboratory to TRL 5.

The team DEVILS propose an electro-mechanical system with which the VPLC adjusts the oil flow independently, acquiring some sensors and elaborating data with internal algorithm; the oil flow is controlled and regulated through a brushless tree-phase DC motor; it moves the regulation element that increases or decreases the oil flow in the lubrication circuit.

The Oil flow Control Unit evaluates the pressure and the temperature of the oil, the angle of the flow regulation and the encoder installed on the pump; with the correlation of these data, a new regulation is evaluated.